Mastering the Embroidery Digitizing Refine: Your Ultimate Overview

Embroidery digitizing is a thorough craft that calls for precision and knowledge to equate elaborate designs right into digital layouts for maker needlework. As craftsmens get started on this trip to master the embroidery digitizing process, a detailed understanding of the essentials establishes the foundation for quality.

Understanding Needlework Digitizing Basics

Needlework digitizing essentials develop the foundation whereupon intricate designs are equated into machine-readable styles for specific sewing. This first action in the embroidery digitizing process is vital for making certain that the final embroidered product is a loyal depiction of the original design. Recognizing embroidery digitizing basics involves understanding crucial principles such as stitch kinds, sew direction, density, rug, and draw settlement.

Stitch types play an important function in establishing the aesthetic and textural end result of the stitched design. By choosing the ideal stitch type, whether it be satin, fill, or running stitch, digitizers can achieve the desired impact and improve the total quality of the needlework. In addition, stitch instructions affects the flow and dimension of the layout, while thickness figures out the spacing and coverage of the stitches.

In addition, rug sewing gives security to the layout by protecting the material and avoiding distortion during the embroidery procedure. Draw settlement is an additional necessary factor to consider to neutralize the all-natural tendency of textile to contract when sewn. Grasping these needlework digitizing essentials is fundamental for producing professional-quality embroidered items.

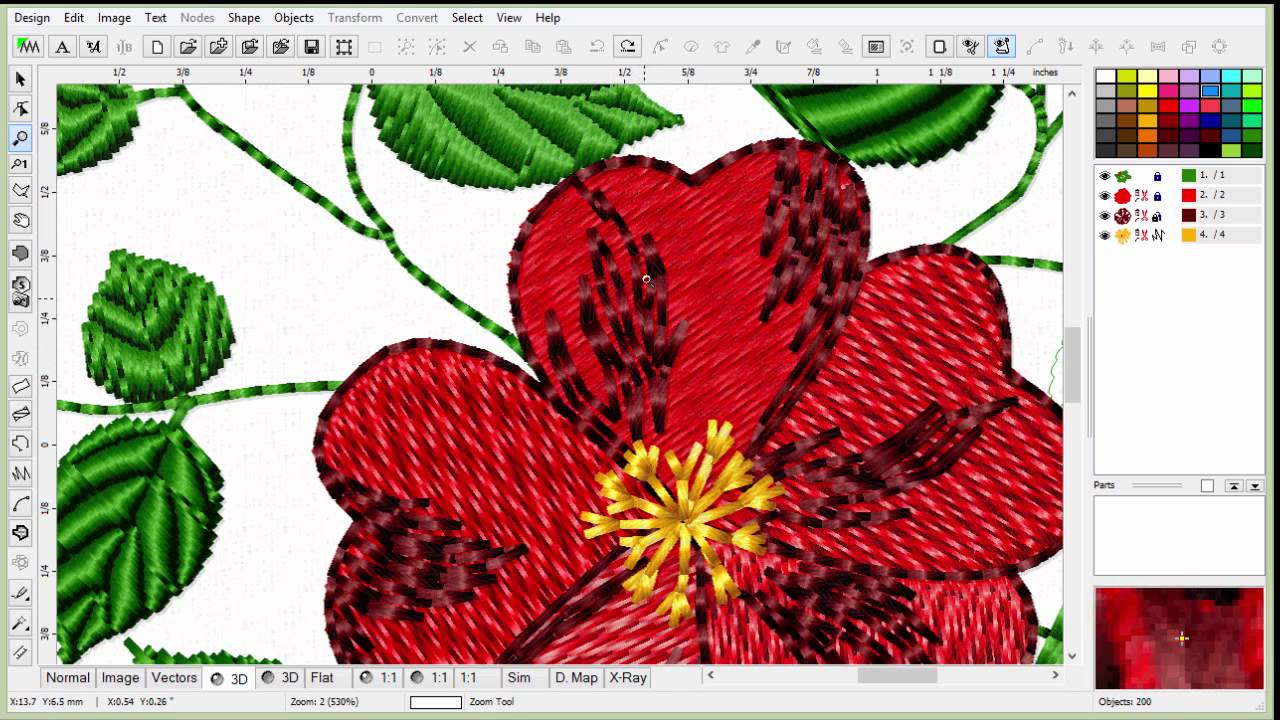

Choosing the Right Digitizing Software Program

Selecting the proper digitizing software is an essential decision that dramatically impacts the performance and quality of the embroidery digitizing procedure. Digitizing for Embroidery. When choosing the ideal digitizing software application, it is vital to consider variables such as the complexity of layouts you prepare to produce, the user-friendliness of the software, the degree of client support supplied, and the compatibility with your embroidery machine

There are various digitizing software program alternatives available on the market, ranging from standard programs for beginners to sophisticated software program for specialist digitizers. Some preferred choices include Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software packages provide a large range of tools and features to aid you develop detailed layouts with convenience.

Before deciding, it is suggested to check out the different software application options through totally free trials or demos to determine which one best matches your needs. Additionally, reading reviews and seeking recommendations from skilled digitizers can offer important insights right into the toughness and weaknesses of each software application plan (Digitizing for Embroidery). By meticulously evaluating your requirements and comparing the attributes of various digitizing software program, great site you can make an educated option that enhances your embroidery digitizing process

Digitizing Tools and Methods

Optimizing Style Setup for Embroidery

Grasping the details of style settings is fundamental in accomplishing optimal outcomes in the embroidery digitizing process, structure upon the foundation laid by recognizing digitizing devices and methods. When optimizing design setups for embroidery, it is vital to consider aspects such as stitch kind, density, rug, draw payment, and enrollment. Registration settings straighten different components of the design precisely, keeping overall layout honesty.

Troubleshooting Common Digitizing Issues

When experiencing usual digitizing problems throughout the needlework procedure, it is vital to comprehend the origin triggers and carry out effective options quickly. One usual problem is stitch thickness concerns, where stitches may be too dense, causing the material to tighten, or as well thin, leading to spaces in the design. Changing the stitch thickness setups in the digitizing software More Help application can help solve this concern.

One more constant difficulty is string breaks during the needlework process. This can take place because of numerous reasons such as incorrect tension setups, boring needles, or using low-grade thread. Making certain correct upkeep of the needlework machine, including routine needle modifications and tension changes, can minimize the occurrence of thread breaks.

Additionally, style enrollment mistakes can result in misaligned elements within the embroidery style. Examining the layout alignment in the digitizing software application and making essential adjustments before stitching can assist in preventing this problem. By resolving these usual digitizing issues quickly and successfully, you can ensure a smoother embroidery procedure and top quality ended up items.

Verdict

To conclude, understanding the needlework digitizing go to my site procedure calls for a solid understanding of the basics, the right choice of software, and knowledge of tools and techniques. Optimizing design setups and repairing usual digitizing concerns are critical action in ensuring top quality embroidery results. By following these actions diligently, one can achieve accuracy and performance in the digitizing process.